Edible oil sunflower oil cooking oil filling and packaging equipment production line

Edible oil sunflower oil cooking oil filling and packaging equipment production line

| Categories | Cooking Oil Filling line |

|---|---|

| Brand | DONGTAI |

| Model | FPML |

| Product name | filling and packaging equipment production line |

| Material | stainless steel |

| Model | FPML |

| Filling range | 1ml-5000ml(can be choosed) |

| Certification | CE,ISO |

| Control | PLC+ touch screen |

| Bottle type | PET/Glass bottle |

| FOB port | Qingdao |

| Terms of Payment | L/C, D/A, D/P, Western Union |

| Update Time | Apr 24,2025 |

This main machine is mainly used for filling packaging various bottled oil, liquid type products, Now it is made of filling machine, labeling machine, coding machine,shrinking packaging macine, unpacking machine, sealing machine.

Certainly, this is belong to forepart packing, ceertainly if you need the whole packaging, we could do it as well.

A, Sunflower oil Production Line is automatic quantitative liquid filling machine, suitable for filling all kinds of oils, such as lubricating oil, edible oil filling, etc.

B, The model of Sunflower oil Production Line is equipped with touch-screen, 8 meters Frequency belt, auto-sensing-based sealer, vacuum anti-drip device

C, Sunflower oil Production Line has a beautiful shape, a high filling precision, convenient adjustment and easy to operate.

D. Man-machine interface, directly set the filling volume;

E. PLC program control, inverter adjust the speed ,filling in line;

F. High-precision positive displacement flowmeters, quantitative accurate and reliable;

G Mechanical seals plus vacuum suck back mack a double anti-drip;

H. Quiklly at first and slow down after ,the double-flow speed make more accuracy effect.

Product name |

Edible oil sunflower oil cooking oil filling and packaging equipment production line |

||

Filling heads |

Eight heads |

||

Filling speed |

1800b/h-2000b/h |

||

Filling range |

1-5L |

Small Bottled Water Production Line is suitable for producing PET plastic containers and bottles in all shapes.

It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Beverage bottle, cosmetic bottle, medicine bottle, jar etc.

Production capacity |

2000b/h,5000b/h,7000-8000b/h |

||

Diameter of bottle |

000b/h,5000b/h,7000-8000b/h |

||

Height of bottle |

150-320mm, 150-320mm, 150-320mm |

||

Power |

0.75kw, 2kw, 1.2kw |

||

Size | 900×700×1850mm, 1200×1000×1800mm, 1500×1200×1900mm | ||

Weight | 350kg, 500kg, 750kg |

Mainly applied to food, grain and oil industries in the square, round bottle-shaped materials, demand for fast automatic labeling, such as: flat bottles labeling, square bottles labeling, with matching oil production line labeling. With the general good, high stability, durability and so on.

1. A unique sub-material bodies, to ensure that the production line on-line use of reliable and effective sub-material.

2. A unique corner of Ful-standard institutions to ensure that the side corner of square bottles labeling three flat, non-wrinkle

3.Labeling Machine is not only stand-alone used, but also used in conjunction with the production line.

1. Material Dimensions: (round bottle) diameter Φ80-Φ150mm; (Square bottle / flat bottle) Length 100-180mm, width 80-180mm, bottles of 50-350mm

2. Labeling speed: Square bottle side / corner of labeling (in 5L bottle square meter): 45 bottles / min

3. Positioning Leaflets labeling round bottle (round bottle with 1.8L total): 35 bottles / min (with the materials and label size related)

4. Labeling accuracy: side labeling position error ≤ ± 1.5mm

5. Round Bottle Labeling weeks to locate position error: ≤ ± 2.0mm

6. Beginning and end error difference: ≤ ± 1.5mm (excluding packaging and labeling pieces of error)

The computer industrial inkjet printer, using the UK Coding technology, For food, medicine, chemical industry, beverage, cosmetics, electronics components and building materials industries play a date code, shelf life of Coding, is the choice of a mass production line.

1. The introduction of the new British Coding ink-drive system with built-in pump

2. The industrial inkjet printer changes to the content of lead in achieving online

3. The industrial inkjet printer is the first to use large print head input method

4. On-line print three lines of numbers in Chinese and English

5. High-speed printing for a variety of materials, can automatically edit the graphic

Specifications |

Specifications of Coding Machine |

||

Print number rows |

1-3 line |

||

Font height |

1.2mm-12mm |

||

Print speed |

2m / s |

||

Print drection | 360 degrees | ||

Print content | Chinese, English, Arabic, picture | ||

Operating humidity | 220V ± 10% VAC, 50Hz | ||

Print format | positive and negative, reverse, back reverse |

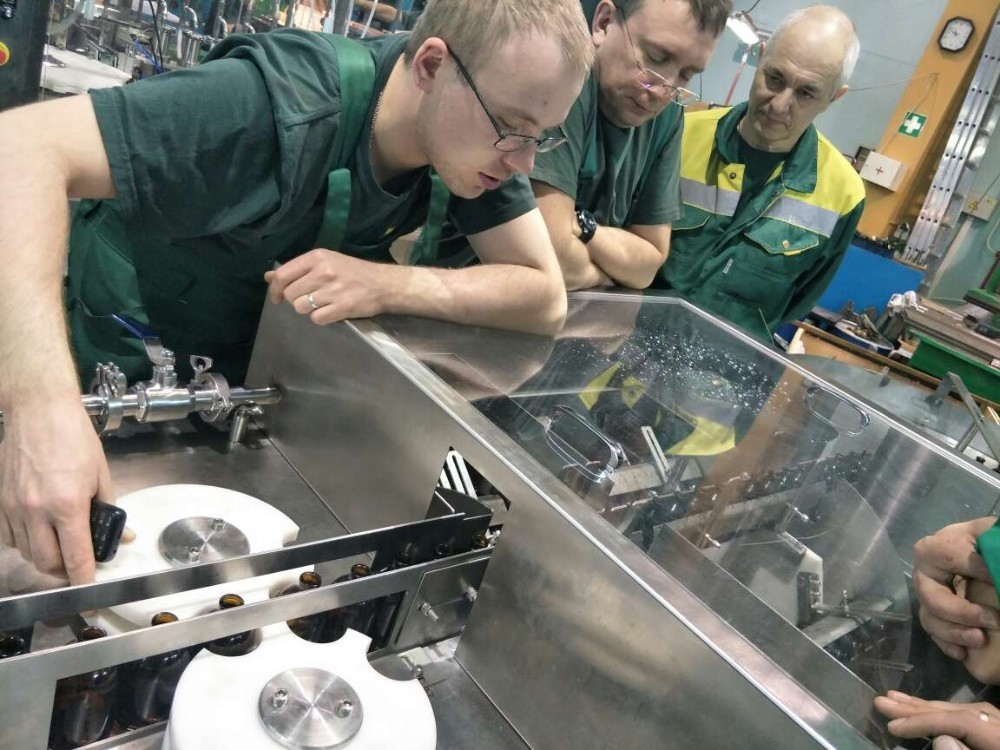

In order to ensure product quality, all suppliers of raw materials, electrical components, and industrial automation that strictly control all aspects of circulation are from well-known brands at home and abroad. They must be strictly inspected by quality inspectors before entering the warehouse. Use, product production is completed, from the assembly plant into the commissioning workshop, after a number of rounds of precision and speed test, after commissioning can be allowed to leave the factory.

Q: How long will take for the delivery of product?

A: customized model depend on customer requirements, usually about 30 days.

Q: What's the insurance of after-sale service after purchase?

A: All our products, will be totally tested by QC department before delivery, with strict quality control process. The product is cost-effective during use, stable and reliable.

One year warranty service for all machine, please feel free to contact us if you have any questions.

Q: When the machine arrives at the work site, is it easy to install? How to solve the problem of quick installation and use?

A: All machine model with installation video, to show the installation process more intuitively, and we will provide remote video technical support to solve your doubts and ensure that your installation is correct.

Install video URL: https://www.facebook.com/groups/1644623782523083/

https://www.youtube.com/channel/UC_wUu5QTxgZsfGRzgxxK29w?view_as=subscriber

(FOLLOW US ON YOUTUBE, TO SEE MORE ABOUT US)

After-sales appointment installation service phone :

+8618560751875 86-531-88168830 engineer Zhang

Q: During the use of the machine, how to get after-sale service?

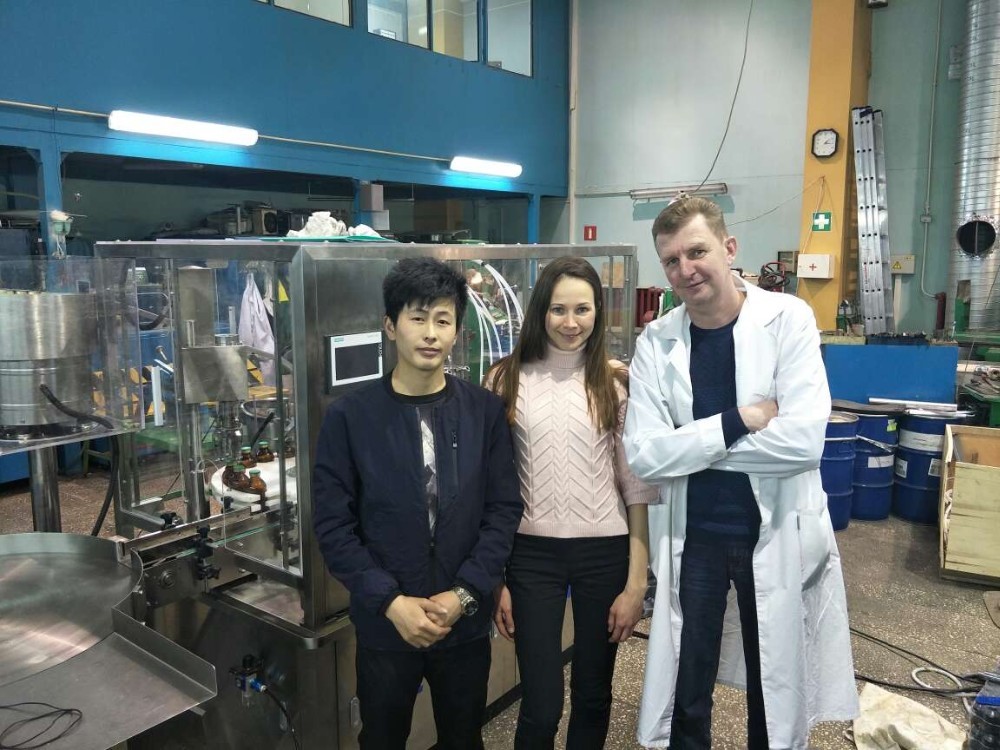

A: We have professional foreign installation and commissioning engineers, which have many years of experience in foreign debugging with deeply recognized by customers. We will provide on-site installation and commissioning services for foreign customers, and we will guide your workers directly.

Q: Will the accessories change frequently with machine ?

A: The service life of the accessories is related to the daily maintenance. When ordering, we will give you free wearing parts and provide you with daily maintenance strategies.

Shandong Dongtai Machinery Manufacturing Co., Ltd. was established in 2008 and is located in Lingang Economic Development Zone, Jinan, China. The company is committed to the design, manufacture and sales of packaging machinery and equipment. It is a high-tech enterprise specializing in the research and development, production, sales and service of automated packaging machinery equipment. The company has professional technicians, engineers and sales and after-sales service personnel, forming a team of high quality, young, highly innovative spirit.

- Tel

- *Title

- *Content

- Name:

- Hilda

- Tel:

86-18660164063

- Email:

- hilda@dongtaipack.com

- WhatsApp:

- https://wa.me/8618660164063

- Address:

- Building 2, Xingfu Liancheng Optoelectronics Innovation Park, No. 1287 Kejia Road, High tech Zone, Jinan City, Shandong Province

Subscribe To Our Mailing List