Automatic case opening machine

| Categories | box opening machine |

|---|---|

| Brand | DONGTAI |

| Applicable carton size | L:250-450; W:150-400; H:100-400mm |

| Temporary storage of carton | 1000mm |

| Unpacking speed | 7-12 cases /min |

| Mechanical size | L200*W1900*H1450mm |

| Voltage | 220V or 380V 50/60HZ |

| Source | 6Kg/cm - 450Ne/min. |

| Power | 200W |

| Tape size | 4860 75mm |

| Update Time | Mar 31,2025 |

Product profiles:

Automatic forming out of the box, the completion of the machine, the bottom folded and

flexed. And now to complete the part of the tape paste, the cardboard box automatically

opened, according to certain procedures or at the bottom of the box, and sealed with tape

after losing to the special equipment of packing machine. Automatic box machine is a high-

volume automatic carton box, automatic folding under cover, automatic sealing tape line

equipment under the bottom of the machine adopts PLC + display control, greatly facilitate

the operation, management, reduce production and labor intensity, is essential for

automated mass production equipment. Convenient operation, reduce the packaging cost.

Type: automatic correcting straight folding grab Angle accurately. The box open compact

design: simple installation for box device: the size of carton box into accurately. Adhesive

tape at the bottom: clean, accurate, touch. This box machine to replace the manual, at

least can reduce 2-3 packages, save 5-10% supplies, improve the efficiency of 30%

greatly, save cost, improve efficiency; more can make the packaging standardization.

Technical parameter:

| Applicable carton size | L:250-450; W:150-400; H:100-400mm |

| Temporary storage of carton | 1000mm |

| Unpacking speed | 7-12 cases /min |

| Machine size | L200*W1900*H1450mm |

| Voltage | 220V or 380V 50/60HZ |

| Source | 6Kg/cm - 450Ne/min. |

| Power | 200w |

| Tape size | 4860 75mm |

Main configuration:

The German SICK photoelectric control system, SIEMENS PLC, Tongli gear motor, AIRTIC

pneumatic components, FESTO vacuum sucker, vacuum generator, Schneider low-voltage

electrical appliances, plexiglass shield, DANFOSS converter, stainless steel parts in

contact with the carton body, carbon steel welded, the surface paint processing.

Working principle:

Through a micro cylinder vacuum cup semi-finished carton to open a square space, and

shaped into a desired shape. By two folding folding arm cylinder and one of the carton

folding in the fold. Then both sides folding inwards into the sealing tape. Then, through the

cylinder and press box components will be inflexed, carton compression you can fold and

seal box into the export production lines, for the next process.

Main features:

This machine adopts photoelectric switch action parts gas electric switch detection signal

input to the PLC (programmable logic controller), control solenoid valve through the PLC

internal procedures and implementation of the machine, pneumatic components, electrical

components are imported devices with high reliability, low failure rate.

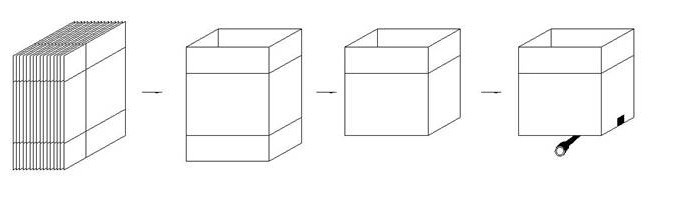

Workflow:

(for carton) - (micro cylinder vacuum suction molding) - (folding cylinder and

folding arm, front and rear folding, then left and right fold) - (tape back cover)

- Tel

- *Title

- *Content

- Name:

- Hilda

- Tel:

86-18660164063

- Email:

- hilda@dongtaipack.com

- WhatsApp:

- https://wa.me/8618660164063

- Address:

- Building 2, Xingfu Liancheng Optoelectronics Innovation Park, No. 1287 Kejia Road, High tech Zone, Jinan City, Shandong Province

Subscribe To Our Mailing List